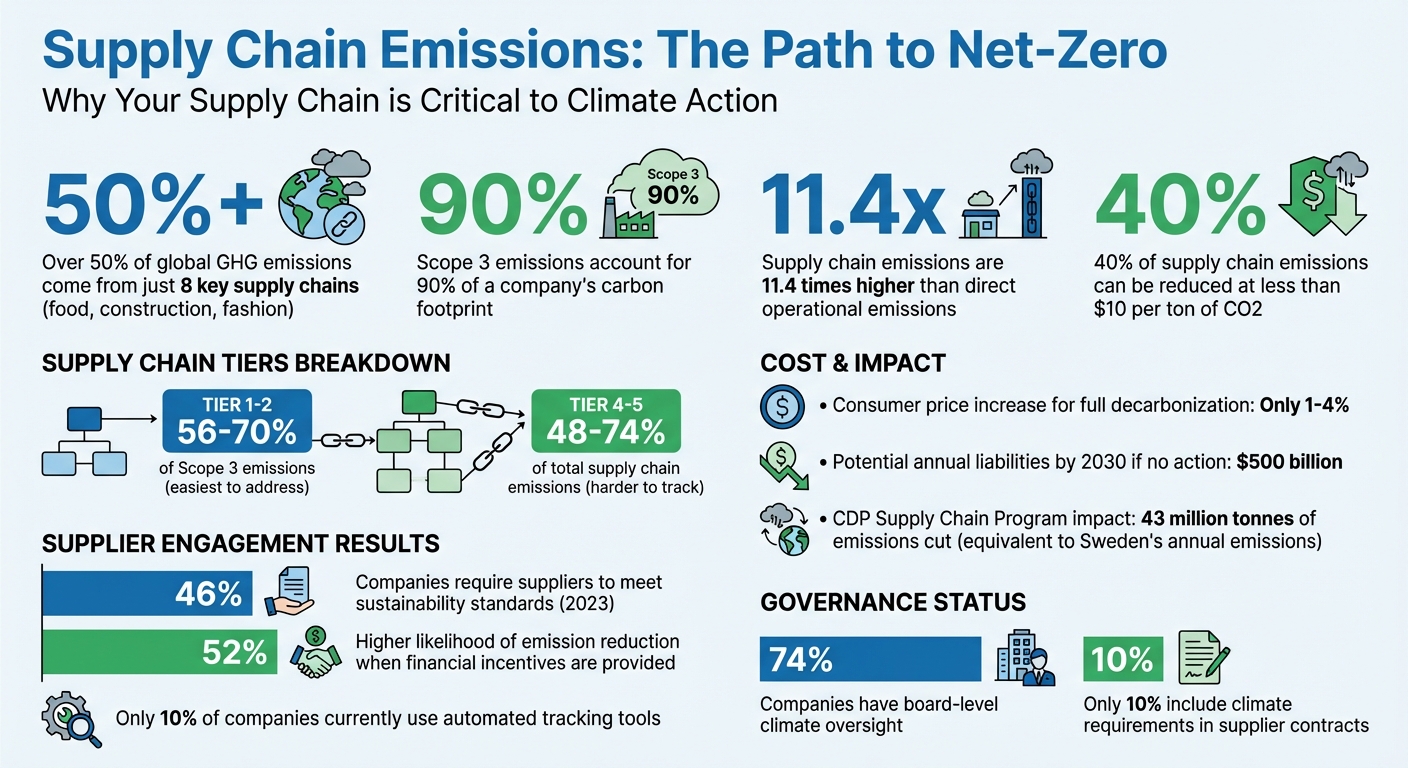

Want to cut emissions effectively? Start with your supply chain. Over 50% of global greenhouse gas emissions come from just eight key supply chains, including food, construction, and fashion. Yet, most companies focus only on their direct operations, ignoring the larger impact of Scope 3 emissions - those generated by suppliers and product lifecycles.

Here’s the good news: 40% of supply chain emissions can be reduced at a cost of less than $10 per ton of CO2. By working with suppliers, measuring emissions, and leveraging AI tools, businesses can significantly reduce their carbon footprint. Collaboration across industries amplifies these efforts, creating shared solutions for long-term success.

Key takeaways:

- Scope 3 emissions matter most: They often account for 90% of a company’s carbon footprint.

- Measure emissions first: Build a baseline using tools like the GHG Protocol.

- Engage suppliers: Offer support, incentives, and clear targets to reduce emissions.

- Use AI tools: Automate tracking, optimize logistics, and identify emission hotspots.

- Collaborate across industries: Join programs like CDP Supply Chain to drive collective impact.

Act now to address supply chain emissions and avoid $500 billion in annual liabilities by 2030. Tackling this challenge isn’t just about compliance - it’s about staying competitive in a low-carbon economy.

Supply Chain Emissions Impact: Key Statistics for Net-Zero Goals

From Supply Chains to Sustainability Chains: A Net Zero Journey

sbb-itb-01010c0

Step 1: Measure Your Current Emissions

To tackle emissions effectively, start by measuring your entire supply chain emissions to set a clear baseline. This involves creating a detailed emissions inventory that spans all 15 Scope 3 categories as outlined by the GHG Protocol Corporate Value Chain Standard.

On average, supply chain emissions are 11.4 times higher than direct operational emissions. For consumer goods companies, Scope 3 emissions typically account for about 90% of their total footprint, with upstream emissions (like purchased goods and services) making up around two-thirds of that. Without precise data, any reduction strategy will lack direction and focus.

Building an Emissions Inventory

Start by mapping your value chain across all 15 Scope 3 categories. Use a screening approach based on your annual procurement spend and EEIO (Environmentally Extended Input-Output) conversion factors. This spend-based method helps you create an initial estimate, even if supplier-specific data isn't available.

Focus on Categories 1, 2, and 4 first, as they usually contribute the most to supply chain emissions. These areas often offer the most immediate opportunities for impactful reductions.

To formalize your efforts, create an Inventory Management Plan (IMP). This plan should detail the tools you'll use, how you'll gather data, and the quality control measures you'll implement. For example, you can use the EPA's default conversion factors to translate activity data - like megawatt-hours of electricity or British thermal units of natural gas - into CO2 equivalent measurements.

Over time, replace general proxy data with primary data collected directly from suppliers through platforms like CDP. This step-by-step refinement improves accuracy, enabling you to shift from rough estimates to meaningful, actionable insights. If Scope 3 emissions make up 40% or more of your total footprint, they must be included in your near-term science-based targets.

Once your inventory is built, focus on the areas with the highest emissions to maximize your reduction efforts.

Identifying the Highest-Emission Areas in Your Supply Chain

To pinpoint where to act first, rank your suppliers and categories to identify the high-emission "vital few." Research indicates that 56% to 70% of Scope 3 emissions are concentrated in the first two tiers of the supply chain. These tiers are often the easiest to address and provide a manageable starting point.

Leverage tools like the GHG Protocol Scope 3 Evaluator to assess which emission sources are most critical. Consider factors such as:

- Size: Activities that significantly contribute to overall Scope 3 emissions.

- Influence: Opportunities to reduce emissions through direct action or collaboration with suppliers.

- Risk: Activities that pose financial, regulatory, or reputational risks due to climate-related issues.

- Stakeholder relevance: Areas deemed important by customers, investors, or other key groups.

While Tier 1 and Tier 2 suppliers are easier to track, achieving net-zero goals often requires looking deeper into Tiers 4 or 5. These deeper levels include carbon-intensive inputs like steel or chemicals, which are especially significant in industries like automotive or electronics. In fact, these lower tiers can represent 48% to 74% of total supply chain emissions, though tracking them is more challenging without industry-wide collaboration.

Here’s some encouraging news: Approximately 40% of emissions in major supply chains can be reduced using existing solutions that cost less than $10 per ton of CO2 equivalent. By identifying the highest-emission areas first, you can allocate resources where they'll make the biggest difference and focus on engaging suppliers who have the most impact.

Step 2: Work with Suppliers to Cut Emissions

After pinpointing high-emission areas, the next move is collaborating directly with suppliers. This partnership increases the chances of meeting Scope 3 emissions goals. The focus should shift from sporadic data requests to fostering ongoing relationships that drive meaningful emissions reductions.

Set Up Supplier Engagement Programs

Start by grouping suppliers based on their emissions impact and strategic importance. This targeted strategy ensures your efforts are concentrated where they matter most, avoiding the dilution of resources across numerous low-impact suppliers.

Develop tiered support systems to address suppliers' varying levels of readiness. For smaller suppliers with limited resources, guide them to free tools like the SME Climate Hub. For key partners, consider offering expert consultations or co-investing in emissions-reducing technologies. For example, the Electric Utility Industry Sustainable Supply Chain Alliance (EUISSCA), a coalition of 16 major U.S. utilities including American Electric Power (AEP), employs a standardized 36-question survey to gather GHG data. This system allows shared suppliers to report their emissions data once, reducing administrative overhead.

Set up "Help Desks" or dedicated technical teams to assist suppliers in GHG accounting and target setting. Many smaller suppliers lack the expertise to handle these tasks. Start with simple data requests - such as asking, "Are you measuring emissions?" - before moving on to more complex quantitative demands.

These structured initiatives create a solid foundation for encouraging suppliers to take active steps toward decarbonization.

Motivate Suppliers to Participate

Incentivize suppliers using both financial and non-financial rewards. Incorporate emissions reduction requirements into contracts, RFPs, codes of conduct, and scorecards. A 2023 survey of over 2,000 executives revealed that 46% of companies already require their suppliers to meet specific sustainability standards.

Use a mix of "carrot" and "stick" strategies depending on the supplier relationship. For critical suppliers, offer benefits like better payment terms, longer contracts, or even co-financing renewable energy projects. For less strategic suppliers, enforce ESG codes of conduct and consider reducing spending if decarbonization targets are not met.

"In these situations, it typically makes much more sense for organizations to rely on the carrot rather than the stick in encouraging and supporting suppliers to reduce their carbon footprints." – Spencer Young, Principal at Deloitte Consulting LLP

Align internal incentives by tying procurement team KPIs to decarbonization objectives, as they manage supplier relationships. Include climate performance in regular supplier evaluations and annual reviews. Share your company’s own success stories to show that tracking GHG data can boost competitiveness, not just cut costs.

Step 3: Expand Collaboration Across Industries

Once you've strengthened supplier engagement, the next step is to think bigger: collaborate across industries. Why? Because a handful of key supply chains are responsible for more than half of global emissions. By working together, industries can achieve far greater impact than they would by acting alone.

Cross-industry partnerships also help level the playing field when it comes to sustainability. When companies align on shared goals and pool resources, they create a stronger demand for low-carbon solutions. This not only makes green technologies more affordable but also encourages investments in decarbonization technologies that might otherwise struggle to scale.

Join Industry-Wide Emissions Programs

There are already several programs designed to help companies tackle emissions collectively. For instance, the CDP Supply Chain Program has become a leader in this space. More than 250 major corporate buyers use this initiative to engage over 47,000 suppliers in tracking and managing environmental data. By 2022, the program included over 340 members with a combined $6.4 trillion in purchasing power. The impact? Suppliers in the program reported cutting 43 million tonnes of emissions - more than Sweden's entire annual emissions.

Another example is the Responsible Business Alliance (RBA), which focuses on electronics manufacturers. It offers a standardized reporting system for greenhouse gases (GHG), water, and waste. Suppliers can enter their data once and decide which customers can access it, simplifying reporting across the global electronics supply chain. Similarly, the Electric Utility Industry Sustainable Supply Chain Alliance (EUISSCA), which includes 16 of the largest U.S. utilities like American Electric Power (AEP), uses a shared questionnaire to streamline supplier reporting. A third party analyzes the data, so suppliers only need to report once for multiple customers.

Other programs address specific challenges. The SmartWay Transport Partnership, led by the EPA, helps companies improve freight efficiency with tools for measurement and benchmarking. The Mission Possible Platform focuses on decarbonizing industries and transport sectors that are especially tough to clean up. For companies pursuing science-based climate goals, the Science Based Targets initiative (SBTi) provides a global framework with over 10,000 businesses committed to reduction and net-zero targets.

Share Resources for Bigger Results

Collaboration doesn’t stop with supplier partnerships - it extends to sharing resources. Pooling resources can speed up decarbonization efforts and make the transition more affordable. For example, joint purchasing groups can increase demand for low-carbon materials, encouraging investment in green technologies.

In sectors where decarbonization is particularly expensive, like heavy industry, joint investments can help overcome financial barriers. By working together, companies can share the costs and expertise needed for green upgrades that might be out of reach individually.

The financial benefits of collaboration are clear. Suppliers are 52% more likely to reduce emissions when buyers provide financial incentives, such as favorable financing tied to environmental performance, compared to just offering training. And the cost to end consumers? Full supply chain decarbonization would only increase prices by 1% to 4% in the medium term. Additionally, about 40% of emissions in major supply chains can be addressed with low-cost solutions, costing less than $11 per ton of CO2 equivalent.

Beyond financial collaboration, cross-sector groups can join forces to advocate for policy changes. A united front can influence policymakers more effectively than individual companies, creating a regulatory environment that supports large-scale decarbonization.

Use AI Tools to Improve Supply Chain Performance

AI tools are transforming supply chain management, especially when it comes to tracking and reducing emissions. Traditional methods of emissions tracking are often time-consuming and prone to errors. AI-powered solutions, however, automate this process, making it more efficient and accurate. In fact, companies that use automated tools are nearly 2.5 times more likely to track emissions thoroughly, yet only 10% of businesses report leveraging such solutions.

These tools do more than just track emissions - they help identify their sources. By analyzing real-time supply chain data, AI pinpoints emission hotspots, enabling targeted action. For example, The Economist Group adopted the CO2 AI data platform to automate emissions measurement. The platform highlighted specific problem areas, allowing the company to collaborate with its highest-emitting suppliers on reduction strategies. Emily Jackson, SVP Sustainability at The Economist Group, noted:

"Measuring emissions is key for monitoring our progress and for KPI and disclosure reporting - but it is a highly repetitive process. It made good business sense to use an automated tool to do this".

These tools align seamlessly with broader initiatives aimed at achieving net-zero supply chains.

AI Process Optimizer for Better Operations

The AI Process Optimizer from The B2B Ecosystem helps businesses streamline operations and reduce inefficiencies that contribute to higher emissions. By analyzing factors like transportation routes, schedules, and workflows, this tool can significantly cut fuel consumption and greenhouse gas emissions. Studies show that AI optimization can reduce emissions by 5% to 10% and save 10% to 20% on fuel costs .

For instance, in 2024, Spanish grocery chain Ametller Origen implemented AI-driven tools for replenishment and forecasting. This led to a 30% reduction in fresh produce spoilage and a 13% cut in inventory value, advancing the company’s goal of achieving CO2 neutrality by 2027 under the leadership of COO Roberto Gómez. Similarly, French retailer Franprix used AI for retail planning, reducing product spoilage by 30%, cutting inventory value by $2.2 million, and lowering stockouts by 67%.

Risk Analyzer for Climate Risk Management

The Risk Analyzer employs predictive models to uncover environmental and governance risks, offering actionable recommendations to address them. It also tracks supplier compliance with environmental standards, an essential function given that upstream Scope 3 emissions from suppliers are, on average, 21 times higher than a company’s direct emissions (Scope 1 and 2). By analyzing diverse data sources - such as court records, sentiment analysis, and satellite imagery - AI can reveal hidden risks and provide a clearer picture of emissions across regions.

For example, the iron and steel industry in India relies on coal for 77% of its energy, compared to just 10% in the United States. This makes geographic sourcing a critical factor in managing climate-related risks.

TAM Analyst for Sustainable Sourcing Options

The TAM Analyst helps companies evaluate supplier combinations to reduce emissions while keeping costs under control. It simulates the impact of adopting low-carbon materials or circular economy practices . This is particularly important since 56% to 70% of Scope 3 emissions occur within the first two tiers of the supply chain.

A great example is Klöckner & Co, which developed the Nexigen PCF Algorithm. This proprietary system has calculated over 200,000 Product Carbon Footprints (PCFs), providing customers with TÜV SÜD-certified data on the carbon footprint of their materials. This transparency allows buyers to make informed choices and opt for greener alternatives. By offering advanced market analysis, the TAM Analyst empowers companies to identify sustainable sourcing opportunities while cutting supply chain emissions.

Policy and Governance for Low-Emission Supply Chains

Strong governance and alignment with regulations are essential for cutting emissions across supply chains. While 74% of companies now have board-level climate oversight, real progress depends on embedding emissions metrics into everyday operations and procurement practices. Below are some strategies and policies that companies can adopt to make this happen.

Align with Government Regulations

Governments are stepping up their role in reducing emissions through stricter regulations and initiatives. For example, Executive Order 14057 sets ambitious goals for federal agencies, including achieving net-zero emissions by 2050 and cutting emissions by 65% by 2030. The "Buy Clean" Initiative further amplifies this effort by using federal purchasing power to prioritize low-carbon construction materials, encouraging sustainable manufacturing practices.

The Securities and Exchange Commission (SEC) has also issued guidance on climate disclosures, reflecting growing concerns among shareholders about climate-related financial risks. On a broader scale, California's Climate Corporate Data Accountability Act and the EU's Corporate Sustainability Reporting Directive (CSRD) are driving more companies to adopt mandatory Scope 3 emissions reporting. To meet these requirements, businesses can align with established frameworks like the Global Reporting Initiative (GRI), CDP (formerly Climate Disclosure Project), and the Supplier Ethical Data Exchange (SEDEX). The CDP Supply Chain initiative, for instance, includes over 340 members with a combined purchasing power of $6.4 trillion as of 2022.

Build Emissions Tracking into Your Governance

To turn sustainability into a core business objective rather than just a compliance task, companies need to integrate emissions metrics into their internal KPIs. Currently, only 10% of companies include climate-related requirements in supplier contracts, highlighting a major area for improvement. A good starting point is appointing a senior sustainability manager to lead these efforts and fostering collaboration between environmental, health, and safety (EHS) teams and procurement departments.

Simplifying data collection is key, especially for smaller suppliers. Tools like the EPA's Supplier Questionnaire on Energy and GHG Emissions can streamline this process. Setting up a "Help Desk" to assist suppliers with limited expertise in emissions reporting can also make a big difference. For companies new to emissions tracking, using spend-based emission factors can help identify high-impact areas. This approach provides a starting point before transitioning to more detailed data collected directly from suppliers.

Conclusion: Reaching Net-Zero Through Supply Chain Collaboration

No company can achieve net-zero emissions on its own. With Scope 3 upstream emissions averaging 21 times higher than a company's direct Scope 1 and 2 emissions, the journey to net-zero relies heavily on addressing the supply chain. Partnering with suppliers can significantly ease the challenges of decarbonization.

Once you’ve established your emissions baseline, forming strong supplier partnerships becomes essential. This can mean co-investing in green technologies, offering technical support, or creating long-term agreements that make decarbonization efforts economically viable. The solutions are already available - and often more affordable than expected.

Supplier collaboration isn’t the only piece of the puzzle. Technology and clear policies are key to ensuring sustainability initiatives deliver measurable and scalable outcomes. For instance, digital tracking systems capable of monitoring emissions at the product level make companies four times more likely to achieve their goals. Meanwhile, robust governance integrates sustainability into procurement practices and performance metrics. As Nigel Topping, UNFCCC's High-Level Climate Action Champion, puts it:

"Supply-chain decarbonization will be a 'game changer' for the impact of corporate climate action. Addressing Scope 3 emissions is fundamental for companies to realize credible climate change commitments".

The stakes are high. Inaction could result in $500 billion in annual transition liabilities by 2030. Yet, the potential rewards are just as significant. Companies that prioritize supply chain sustainability don’t just cut their carbon footprint - they also enhance resilience against climate risks, stand out in the marketplace, and position themselves for long-term success. With eight global supply chains responsible for over 50% of all greenhouse gas emissions, coordinated, cross-industry efforts can amplify local supplier initiatives into meaningful global climate action.

FAQs

What are Scope 3 emissions, and why do they matter for achieving net-zero goals?

Scope 3 emissions are the indirect greenhouse gas emissions that stem from a company’s entire value chain. These emissions come from sources the company doesn’t directly own or control, such as the production of purchased goods, transportation, product use, and disposal.

They matter because Scope 3 emissions often make up the largest portion of a company’s carbon footprint. Reducing them is essential for reaching net-zero goals. This process involves working closely with suppliers and partners to measure, manage, and cut emissions. Addressing Scope 3 emissions not only supports sustainability efforts but also showcases climate leadership and strengthens long-term business stability.

How can AI tools help businesses lower supply chain emissions?

AI tools are reshaping how businesses tackle supply chain emissions by offering real-time visibility and actionable insights. By crunching massive amounts of data, AI can calculate carbon footprints across all supplier levels, pinpointing the biggest emission sources - particularly within Scope 3 emissions, which are often the hardest to track.

On top of that, AI enhances demand forecasting and inventory management, helping businesses avoid overproduction and unnecessary shipments. It also fine-tunes transportation logistics by optimizing routes and consolidating loads, which means less fuel burned and lower CO₂ emissions. For instance, dynamic route adjustments in a U.S. distribution network could cut thousands of pounds of CO₂ emissions annually.

AI isn’t just about tracking emissions - it also fosters supplier collaboration. By assessing suppliers’ carbon performance and automating sustainability efforts, AI-powered tools like dashboards help companies focus on impactful actions, measure progress, and integrate sustainability into their daily workflows. Businesses can even translate these efforts into measurable outcomes, showing both dollars saved and emissions avoided. In this way, AI becomes an essential partner in the journey toward net-zero goals.

How does cross-industry collaboration help reduce supply chain emissions?

Addressing Scope 3 emissions - the indirect greenhouse gas emissions tied to a company’s supply chain - requires teamwork. Businesses need to join forces with suppliers, industry peers, and other stakeholders to make a real impact. This kind of collaboration is especially crucial in industries like electronics, automotive, and construction, where reducing emissions can be particularly tough. By working together, companies can scale up their efforts, speed up climate action, and move closer to their net-zero goals.

On the financial side, transitioning to a net-zero supply chain is surprisingly affordable. Research indicates that the cost increase for consumers would be minimal - think less than $1 added to a $40 product. Beyond cost, collaboration can spark shared innovation, cut down inefficiencies, and give businesses a competitive edge by positioning them as leaders in sustainability. In the U.S., companies have access to platforms like The B2B Ecosystem, which offer tools and resources to connect with partners, align on carbon reduction goals, and monitor progress in ways that meet U.S. standards.